Extractor Fan Maintenance Scheduler

Maintenance Tasks Overview

Track your extractor fan maintenance tasks with this interactive scheduler.

Safety Reminder

Always turn off power before servicing. Use a voltage tester to confirm.

Upcoming Maintenance Tasks

Maintenance Timeline

Filter Maintenance

Clean every 3 months to prevent grease buildup and maintain airflow.

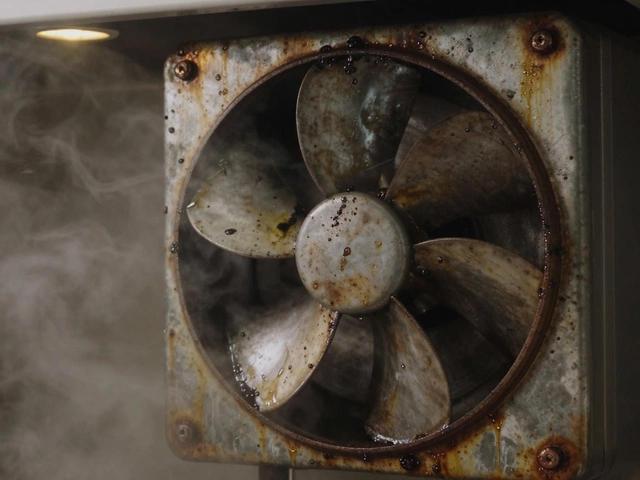

Blade Cleaning

Wipe blades and housing every 6 months to reduce noise and wear.

Extractor fan servicing isn’t rocket science - with the right tools and a step‑by‑step plan you can get it running smoothly again and avoid costly call‑outs.

Key Takeaways

- Turn off electricity before you start.

- Remove and clean the filter at least every three months.

- Check the duct for blockages annually.

- Inspect the motor and wiring for wear each year.

- Re‑test fan speed after reassembly to confirm proper airflow.

Understanding Your Extractor Fan

When we talk about an extractor fan is a ventilation device installed in kitchens or bathrooms that pulls moist or odorous air out of the room and pushes it through a duct to the outside. Typical specs include an airflow rating of 300-900CFM (cubic feet per minute) and a power draw of 40-70W. Extractor fans come in wall‑mounted, ceiling‑mounted or inline varieties.

The core components you’ll be working with are the motor a 120‑V, 50‑60Hz brushless unit that spins the fan blades at 1,200-1,800RPM, the filter usually a removable aluminium or charcoal mesh that traps grease and dust; mesh size is typically 0.5mm, the duct a rigid aluminium tube that carries the extracted air to the exterior; common diameters are 100mm or 150mm, and occasionally a humidity sensor a small electronic module that boosts fan speed when moisture levels exceed 60%. Knowing where each lives helps you target the right cleaning step.

Safety First

Before you lift the cover, always switch off the circuit at the breaker. A quick test with a non‑contact voltage tester confirms the wires are dead. If the fan is ceiling‑mounted you’ll likely need a ladder a sturdy, 6‑foot step ladder with anti‑slip feet. Keep a screwdriver Phillips‑head, 5‑inch tool handy for removing screws, and wear gloves to protect your hands from sharp edges.

Step‑by‑Step Service Procedure

- Power down and secure the work area. Flip the breaker, place a warning sign, and double‑check with a voltage tester.

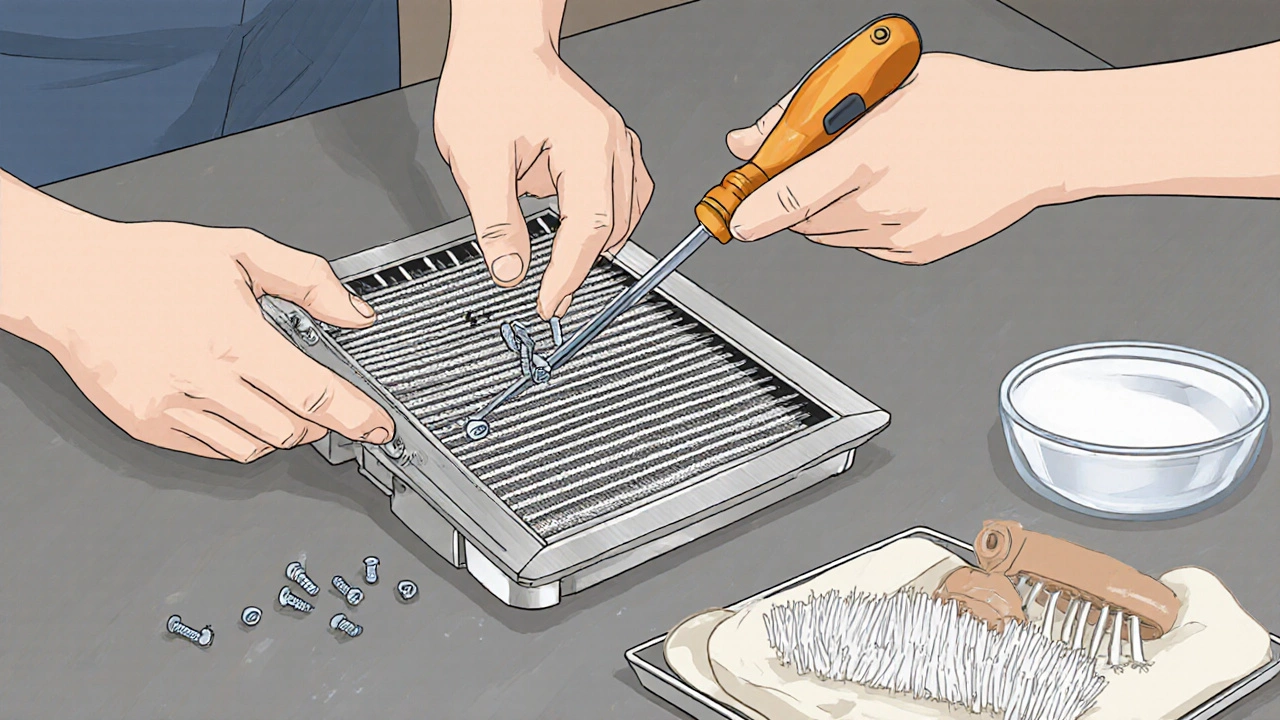

- Remove the outer grille. Most fans have 3‑4 screws. Use the screwdriver to loosen them, then gently pull the grille away. Set the screws in a small tray.

- Take out the filter. The filter slides out or lifts off. If it’s a metal mesh, tap it lightly to dislodge grease. Soak it in hot, soapy water for 10minutes, then rinse and let dry completely.

- Clean the fan blades and motor housing. Using a soft cleaning brush a 3‑inch nylon brush with stiff bristles, wipe away dust and accumulated grease from the blades. For stubborn grime, dip a cloth in a 1:1 mix of water and white vinegar, then wipe clean. Avoid spraying liquids directly on the motor.

- Inspect the motor and wiring. Look for any frayed insulation, burnt marks, or loose connections. If you spot damaged wires, tighten the terminals or replace the motor coil - this is usually a job for a professional.

- Check the duct for blockages. Detach the duct from the fan housing (usually a clamp or screw). Shine a flashlight inside; if you see soot or bird‑nest material, clean it with a flexible duct brush. Re‑attach the duct ensuring a tight seal.

- Re‑assemble the fan. Place the filter back, secure the grille with the saved screws, and restore power at the breaker.

- Test the operation. Turn the fan on. You should hear a steady, low‑hum and feel a noticeable airflow at the grille. If the speed seems low, revisit the duct connection or the motor brushes.

Maintenance Schedule & Tips

Regular upkeep keeps the fan efficient and extends its life. Below is a handy schedule you can paste onto your fridge.

| Task | Frequency | Why it matters |

|---|---|---|

| Clean filter | Every 3 months | Prevents grease buildup that reduces airflow |

| Wipe blades & motor housing | Every 6 months | Reduces noise and wear on bearings |

| Inspect duct | Annually | Avoids blockages that can cause back‑pressure |

| Check wiring & motor | Annually | Catches early signs of electrical failure |

Extra tips: use a shop‑vac with a narrow hose attachment for the filter, avoid abrasive cleaners on metal parts, and always let components dry completely before re‑assembly.

Common Problems and When to Call a Pro

Even with diligent care, some issues need a trained technician. Look out for:

- Motor humming but no airflow. Likely a burnt bearing - replacement is best left to a pro.

- Intermittent operation. Could be a faulty humidity sensor or loose wiring.

- Excessive vibration. May indicate a bent blade or misaligned motor mount.

- Persistent bad smells. Might be a duct leak that’s pulling in attic air; seal with foil tape.

If you encounter any of these, replace the part or schedule a professional service to avoid safety hazards.

Frequently Asked Questions

How often should I clean the extractor fan filter?

A good rule of thumb is every three months, or sooner if you do a lot of frying. Regular cleaning stops grease from choking the motor.

Can I use a regular household vacuum on the fan blades?

Yes - attach the narrow hose and a soft brush head. Avoid the brush roller; it can scratch the metal blades.

What safety gear do I need while servicing?

At minimum wear insulated gloves, safety glasses, and a dust mask if you’re cleaning a greasy filter. A stable ladder or step stool is essential for ceiling fans.

Should I lubricate the motor bearings?

Most modern extractor fans have sealed bearings that don’t need oil. If the manufacturer specifies a light silicone spray, use only a few drops.

How do I know if the duct is sized correctly?

Check the fan’s spec sheet - it will list the recommended duct diameter, usually 100mm for residential units. A duct that’s too small causes back‑pressure and louder operation.

What signs indicate the motor needs replacement?

Listen for grinding noises, notice a drop in airflow, or feel the fan stall when you turn it on. Warm spots on the housing also point to a failing motor.