When your home stops heating or cooling the way it should, the first suspect is often the heat pump is a hybrid HVAC system that moves heat between indoor and outdoor spaces using a refrigerant cycle. It can both heat and cool a home, making it a popular choice in moderate climates. Figuring out whether it’s simply dirty, needs a tweak, or is truly broken saves you time, money, and the chill of a cold house.

Typical Symptoms of a Faulty Heat Pump

Before you grab a screwdriver, run through these common clues. If you notice any of them, you’re likely dealing with a heat pump malfunction that needs attention.

- Blowing warm air when you’re set to cool (or vice‑versa).

- Long start‑up delays - the fan spins but the compressor stays silent.

- Frequent cycling on and off, which can raise energy bills.

- Unusual noises: rattling, squealing, or humming that wasn’t there before.

- Ice buildup on the outdoor unit that won’t melt.

- Water leakage around the indoor blower or outdoor coil.

These signs point to different components, so matching symptom to cause speeds up the diagnosis.

Key Components to Inspect

Understanding what each part does helps you pinpoint the problem. Below are the most common culprits.

Compressor is the heart of the heat pump, compressing refrigerant so it can release or absorb heat. A humming sound without pressure build‑up usually means the compressor is stuck or dying.

Thermostat controls the temperature set‑point and tells the heat pump when to run. A mis‑calibrated thermostat can trick the system into the wrong mode.

Refrigerant is the fluid that carries heat through the cycle. Low charge or leaks reduce efficiency and cause frosting.

Evaporator coil sits inside the indoor air handler; it absorbs heat from the indoor air. If it’s clogged, airflow drops and the coil can freeze.

Condenser coil is the outdoor heat‑exchanger that releases heat to the outside (or absorbs it in heating mode). Dirt here forces the compressor to work harder.

Air filter traps dust before it reaches the indoor coil. A dirty filter chokes airflow, leading to overheating or icing.

Defrost timer triggers a short heating cycle to melt ice on the outdoor coil. If it fails, ice can build up continuously.

Circuit breaker protects the system from overload. A tripped breaker will stop the unit dead in its tracks.

Step‑by‑Step Troubleshooting Checklist

- Turn off power to the unit at the breaker. Safety first.

- Inspect the air filter. If it’s visibly dirty, replace it.

- Look at the outdoor condenser coil. Clear any leaves, debris, or spider webs.

- Check the circuit breaker. Reset it if it’s tripped.

- Listen for the compressor. A steady hum means it’s trying to start; silence could indicate a bad start capacitor.

- Feel the refrigerant lines. Warm in heating mode, cool in cooling mode. Extreme temperature differences may signal low refrigerant.

- Watch for ice on the evaporator coil or outdoor unit. If present, run the defrost cycle manually (consult the user manual).

- Verify thermostat settings. Ensure it’s set to “auto” mode and the temperature is correctly entered.

If any step uncovers a clear fault-like a clogged filter, blocked coil, or tripped breaker-fix that first. Often the problem resolves without a professional call.

When to Call a Professional

Some issues need tools and expertise that only a licensed technician has. Call a pro if you encounter any of the following:

- Persistent compressor silence after checking the breaker and capacitor.

- Suspected refrigerant leak (you’ll notice oily spots or a drop in performance).

- Repeated ice buildup despite a working defrost timer.

- Electrical smells, sparks, or burnt wiring.

- Complex control board errors indicated by flashing LED codes.

Attempting DIY repairs on the refrigerant circuit or electrical components can be hazardous and may void warranties.

Preventive Maintenance Tips

Regular care keeps your heat pump humming smoothly year‑round.

- Replace the air filter every 30‑60 days during heavy use.

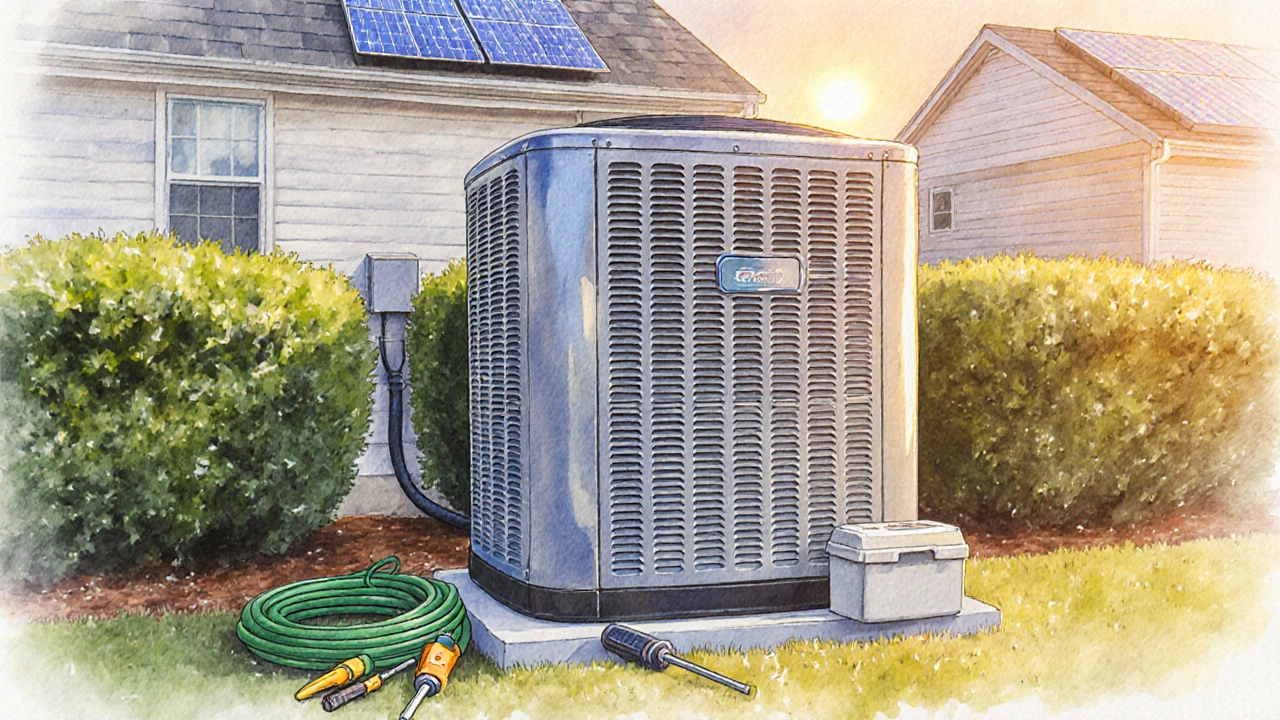

- Clean the outdoor condenser coil annually; a garden hose on low pressure does the trick.

- Schedule a professional service before the seasonal switch-once in spring, once in autumn.

- Trim vegetation at least 2 feet away from the outdoor unit for proper airflow.

- Check the defrost timer and thermostat batteries yearly.

Comparison Table - Symptoms vs. Likely Causes

| Symptom | Most Common Cause | First Action |

|---|---|---|

| No heating or cooling | Tripped circuit breaker or faulty compressor | Reset breaker, listen for compressor hum |

| Air feels weak or uneven | Clogged air filter or dirty evaporator coil | Replace filter, clean coil |

| Ice on outdoor unit | Defrost timer failure or low refrigerant | Run manual defrost, check refrigerant pressure |

| Loud rattling noises | Loose fan blades or damaged motor bearings | Turn off power, inspect fan assembly |

| Frequent short cycles | Thermostat mis‑set or undersized unit | Verify thermostat mode, consider professional sizing |

Frequently Asked Questions

How long should a heat pump run before it’s considered a problem?

If the unit runs more than 15 minutes continuously without reaching the set temperature, or if it shuts off after a few seconds repeatedly, something is likely wrong.

Can I add refrigerant myself?

No. Handling refrigerant requires certification and special equipment. Adding it yourself is illegal in many regions and can damage the system.

Why does my heat pump make a buzzing sound?

A buzzing tone often points to the compressor’s start capacitor struggling. It may need replacement, but first check the breaker and power supply.

Is it normal for a heat pump to drop temperature a few degrees during the first few minutes?

Yes, the system needs a short ramp‑up period. If the temperature drops and stays low, then it’s a sign of a deeper issue.

How often should I schedule professional maintenance?

Twice a year-once before the heating season and once before cooling-keeps the refrigerant levels, electrical connections, and coils in good shape.